|

||

|

|

|

As Intimate Fashion endeavors to continue being a leading manufacturer of underwear, no expense has been spared in the investment of its two modern facilities. Only the best of machinery, equipment and tools are used in the making of extraordinary underwear.  In addition, Intimate Fashion is one of the very few manufacturing companies that operate its modern factories with full air-conditioned unlike most factories that are open-aired. Although this option is quite costly, Intimate Fashion approve of it as cleanliness of the highest level is guaranteed and contributes in creating a healthier and better work and manufacturing environment. Intimate Fashion is also one of the few unique underwear manufacturer that provides the option of adding bra support materials into a variety of products to enhance appearance and support. The following is a breakdown of the various departments of Intimate Fashion production line. |

||

Utilizing CAD with CAM enables Intimate Fashion to produce underwear to its clients?exact requirements right down to the finest detail. Each stitch, cut, and pattern is manufactured to the millimeter. During production stages, sophisticated CAD and CAM computer software and Microdynamic Gerber machinery are used together to manufacture creative and attractive underwear that consists of fine, detailed patterns.  To see our visual factory (QTVR 360°), you have to download Quick Time player.  Intimate Fashion, a total solution provider, acknowledges its clients' possible need for such an option, and have therefore, added it to its production line. To see our visual factory (QTVR 360°), you have to download Quick Time player. |

||

|

||

| A team of professional buyers,

who have the hindsight of future market trends, has been formed by

Intimate Fashion to ensure that it has more that sufficient stock

to assist its clients in their quest for attractive and good quality

underwear. Extensive searching for new and innovative fabrics and

raw materials are constantly undertaken, as these allow for attractive

and revolutionary underwear. All acquired stock are then required

to undergo Formalin prevention, and this takes place by Intimate Fashion's

in-house state-of-the-art test laboratory. To see our visual factory (QTVR 360°), you have to download Quick Time player.  |

||

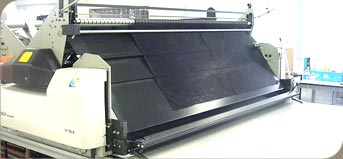

Intimate Fashion is a few manufacturer that operates an Auto-Cut machinery that works with CAM, but nobody else has possesses 2 of such hi-tech machinery in its factory except for Intimate Fashion. Doing so, Intimate Fashion is constantly able to meet up with any client's manufacturing requirements.  Furthermore, at Intimate Fashion, there is also the Lace Press Machinery and the unique Roller-Cut Machinery. These machines were specifically acquired as they specialize in the production of underwear that involves complex details, ideal for Intimate Fashion as details concerning the entire underwear production process is top priority. The Roller-Cut technology from Japan, few manufacturers are able to offer this costly facility, thus, rarely used. Intimate Fashion, a total solution provider, acknowledges its clients' possible need for such an option, and have therefore, added it to its production line. Playing a crucial in the making of underwear that fit right, specialize molding equipment are operated by experience professionals at Intimate Fashion. With a total of 22 different molding machinery, Intimate Fashion is the sole underwear manufacturer in Thailand that possess such an extensive array of molding equipment.  |

||

| << Back | Top | Next >> | ||

©2003 All Rights Reserved. Intmate Fashion Co.,Ltd. Created and Designed by